Product Introduction

-

JP

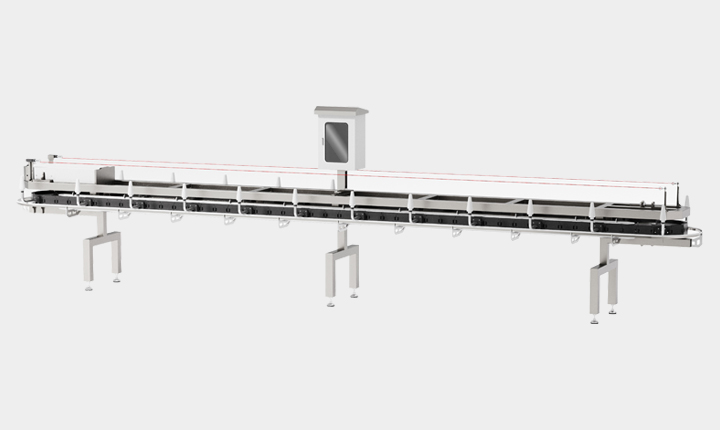

CONCone Disassembly Machine

Collaborative Robots Working Alongside Operators

Wide range of applications with a various lineup

Wide range of applications with a various lineupAn automated machine designed to enable workers to disassemble each part.

×- Automatic Transport by Securing Chickens on Cones

The cone disassembly machine secures chickens on a cone-shaped support and moves them automatically, allowing workers to efficiently disassemble each part. This reduces worker fatigue compared to manual labor and maximizes productivity.

- Minimized Worker Movement & Maximized Efficiency

Since the chickens move automatically, unnecessary worker movement is minimized, significantly enhancing the efficiency of the disassembly process. The consistent processing speed ensures uniform quality in disassembly operations and supports production process optimization.

- Safety and Integrated Automation System

The cone disassembly machine is equipped with safety sensors and control systems to ensure worker safety. Additionally, it can be integrated with a C/V (conveyor) system to build an efficient production line, providing an optimized solution for poultry processing automation. ※C/V installation is separate.

Use Cases

Machine Specifications

- Product

-

-

Structure

Stainless steel angle pipes, stainless steel bending structure

-

Operating Voltage

3P 380V

-

Power consumption

1 KW

※ It varies depending on the C/V installation.

-

Structure

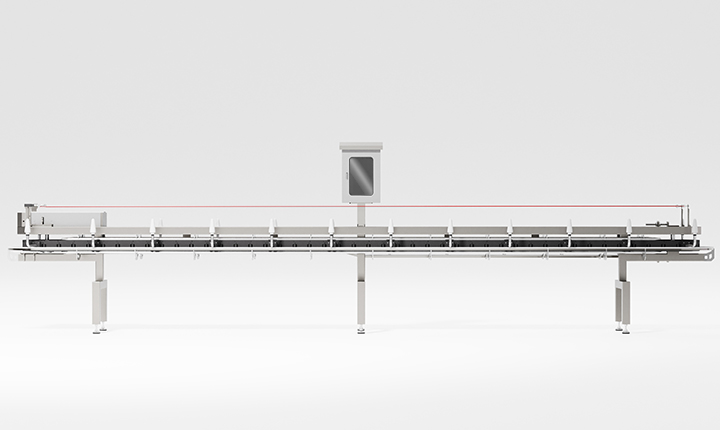

- Machine Size

※ The overall size

varies depending

on the client's

production request. -

-

Width

7,386mm

-

Depth

1,020mm

-

Height

1,975mm

-

Width

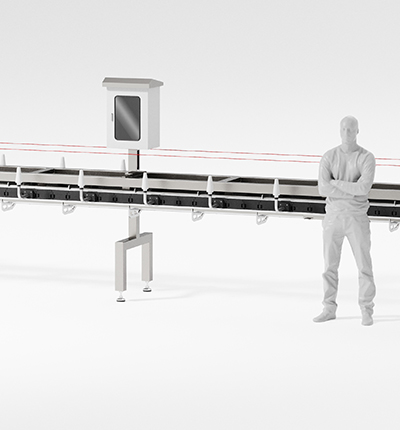

- Operator

-

-

Operator

1 person

※ It varies depending on the number of personnel the client wants to assign.

-

Operator

-